Protein Engineering of Penicillin Acylase

- Authors: Tishkov VI1,2,3, Savin SS2,3, Yasnaya AS2,4

-

Affiliations:

- Lomonosov Moscow State University

- Bach Institute of Biochemistry, Russian Academy of Sciences

- Innovations and High Technologies MSU Ltd

- National Research Center "Kurchatovskii Institute"

- Issue: Vol 2, No 3 (2010)

- Pages: 47-61

- Section: Articles

- Submitted: 17.01.2020

- Published: 15.09.2010

- URL: https://actanaturae.ru/2075-8251/article/view/10759

- DOI: https://doi.org/10.32607/20758251-2010-2-3-47-61

- ID: 10759

Cite item

Abstract

Penicillin acylases (PA) are widely used for the production of semi-synthetic β-lactam antibiotics and chiral compounds. In this review, the latest achievements in the production of recombinant enzymes are discussed, as well as the results of PA type G protein engineering.

Keywords

Full Text

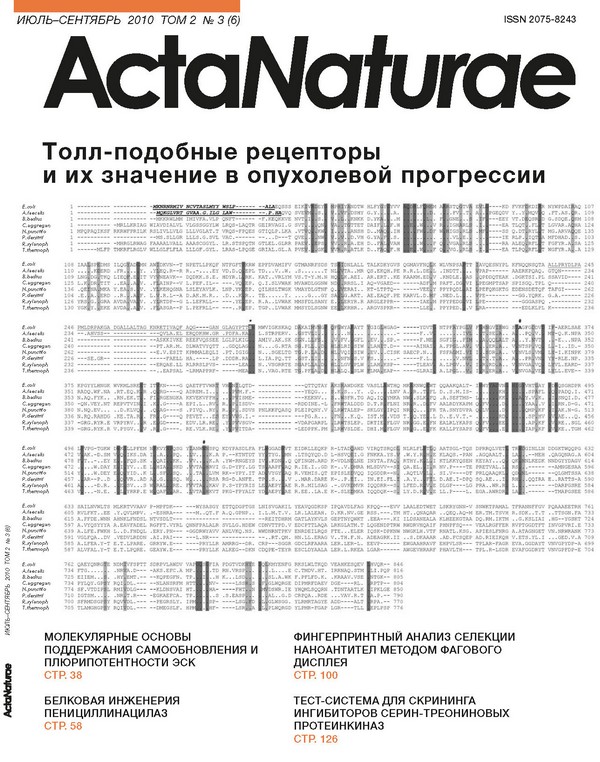

ABSTRACT Penicillin acylases (PA) are widely used for the production of semi-synthetic β-lactam antibiotics and chiral compounds. In this review, the latest achievements in the production of recombinant enzymes are discussed, as well as the results of PA type G protein engineering. KEY WORDS penicillin acylase, E.coli, expression, structure, protein engineering ABBREVIATIONS PA - penicillin acylase, EcPA and AfPA - penicillin acylases from Escherichia coli and Alcaligenes faecalis, respectively, 6-APA - 6-aminopenicillanic acid, D-PGA - D-phenylglycine amide, FAA - phenylacetic acid. INTRODUCTION Penicillin acylase (PA, EC 3.5.1.11) was discovered 60 years ago as a catalyst of the hydrolysis of the amide bond in penicillin antibiotics [1]. This enzyme belongs to the class of hydrolases, a subclass of aminohydro-lases, and represents a group of so-called N-terminal nucleophilic hydrolases. PA has been found in bacteria, yeast, and fungi. The physiological role of the enzyme remains poorly understood. It seems possible that its main function is in utilizing heterocyclic compounds as a source of carbon. PA has been extensively studied for more than 50 years. In practice, this enzyme is commonly used to produce 6-aminopenicillanic acid, which is the main synthon in the synthesis of penicillin antibiotics. PA is also used for the synthesis of various semi-synthetic P-lactam antibiotics. Broad substrate specificity and high regio-, chemo- and stereoselectivity of the enzyme are used for the production of chiral compounds (which are more and more in demand in modern pharmaceutics), as well as for the protection of hydroxy and amino groups in peptide and fine organic synthesis. Currently, the most commonly used PA is that from Escherichia coli (EcPA). This enzyme has been better studied and characterized in comparison with the other PAs; however, the efficiency of the acyl transfer into P-lactam cores, catalysed by EcPA, is not high enough to make the enzyme competitive as compared with the out-of-date methods of antibiotic synthesis. At the same time, intensive spreading of pathogens resistant to currently available antibiotics has inevitably prompted the search for new antimicrobial compounds with artificial side chains. The catalytic efficiency of wild type PA would be too low for the synthesis of these substances: therefore, preparation of new mutant enzymes with improved synthetic parameters with artificial substrates is of great importance for practical and fundamental science. Another, equally important problem is improving a PA’s stereoselectivity in reactions of amino-alcohols acylation and hydrolysis of N-acyl derivatives, since a PA’s stereoselectivity in reactions of amino-alcohols production is incomparably lower than for amino acids. New enzymes with improved properties can be obtained by various means: for example, random mutagenesis (directed evolution, gene shuffling, etc.) and site-directed mutagenesis based on an analysis of 3D protein structures (rational design). The second approach has become more widespread; however, it requires knowledge of the enzyme’s 3D structure, which can be obtained in an experiment (X-ray diffraction, NMR) or by computer modeling. In the present review we will discuss the recent achievements in the production of recombinants PAs with improved properties. CLASSIFICATION OF PENICILLIN ACYLASES Penicillin acylases represent a group of P-lactam acy-lases and can be classified according to the type of the hydrolysed substrate. Therefore, enzymes can be grouped as those that hydrolyse penicillin G, penicillin V, or ampicillin. In 1963 it was suggested to divide penicillin acylases into classes I and II [2]. Class I enzymes basically hydolyse penicillin V (phenoximethylpenicil-lin), while class II enzymes use penicillin G (benzylpeni-cillin) as a substrate. Later, the class III, including the enzymes which hydrolyse ampicillin, was added [3-6]. Fig. 1. Modern classification of P-lactam acylases according to the type of substrate [7]. 7-ACA -7-aminocepha-losporanic acid P-Lactam acylases Cephalosporins Penicillins COOH NH Cephalosporin C o nh2 Penicillin G Penicillin V Ampicillin nh2 Glutaryl 7-ACA Glutaryl Phenylacetyl Knacc I Phenoxyacetyl II a-Aminoacyl 5-Aminoadipyl III IV a-Acylamino-P-lactam acylhydrolases An up-to-date classification of acylases of P-lactams according to the preferred substrate core structure and side chains [7] is shown in Fig. 1. According to this classification, class II PAs can be additionally divided into two subgroups: class IIa - enzymes that basically hydrolyse aromatic amides, and class IIb - enzymes that hydrolyse aliphatic amides [7, 8]. SOURCES AND LOCALIZATION OF PENICILLIN ACYLASES The activity of penicillin acylase was described for the first time by Japanese scientists in 1950 [1]. They found that the mycelium of both Penicillium chrysogenum and Aspergillus oryzae was able to convert benzylpen-icillin into phenylacetic acid and another compound, which the authors called “penicin” and which was later identified as 6-aminopenicillanic acid (6-APA) [1, 9, 10]. More detailed studies of this enzyme were carried out in the 1960s. At the time, a large number of papers on the enzyme properties, and its potential application, were published. Today, the amount of papers devoted to penicillin acylases increases with every year. It should be noted that penicillin acylase activity was also detected in bacteria, yeast, and fungi [11-14]. At the present time, PAs from more than 40 different microorganisms have been described. Many genes of penicillin acylases were found in annotated genomes of microorganisms. Depending on the species of the microorganism, the enzyme can dwell either outside or inside the cell. Localization in periplasma is chrachteristic for active forms of G-class penicillin acylases (class II). Extracellular expression is also typical for some strains producing penicillin acylases V (class I) and penicillin acylases G (class II). The physiological role of PAs remains unclear despite a 60-year-long history of studying them. It is highly probable that PAs are needed for the utilization of aromatic amides as carbon sources [15]. Basic properties of some well-studied penicillin acylases are presented in Table 1. CHARACTERISTIC FEATURES OF PENICILLIN ACYLASE G EXPRESSION PA-G gene encodes a precursor polypeptide which consists of 4 structural elements: a signal peptide, a-and P-subunits, and an inter-subunit spacer. The mature PA-G molecule is a heterodimer with a molecular weight of 86 kDa. It consists of two subunits, a- and P-, with molecular masses of 23 and 63 kDa, respectively [23, 24]. In addition, the molecule contains a bound Ca2+ ion, which, according to data, is important for enzyme processing [18]. Posttranslational modification of PA-G is a multistage process, which has been well studied for the enzyme from E.coli. The first step includes transport of the inactive precursor from the cytoplasm to the peri-plasmic compartment, a process drived by the signal peptide, which is then removed after the transport is completed. Afterwards, the inter-subunit spacer undergoes two-step proteolysis, which results in the formation of an active heterodimer [23, 25, 26]. In E.coli cells, transport of most of the proteins across the membrane is mediated by Sec-translocase. Sec-system recognizes signal peptides that do not have similar sequences but are quite close in their physico chemical properties. SecB-chaperone recognizes a short sequence containing aromatic and positively charged amino acids, which subsequently is processed by Sec-translocase [27]. SecB is a basic component that participates in the translocation of many secretory and peri-plasmic proteins. In work [28], it was shown that SecB is essential for EcPA-G maturation. Table 1. Main characteristics of penicillin acylases from different sources Class Source Preferable substrate* Induction of biosynthesis Cell localization References Class I PA-V Streptomyces lavendulae Pen-V, Pen-K no outside [3] Dermatophytes Pen-V yes inside [3] Penicillium chrysogenum Pen-V, Pen-K yes inside [3] Bacillus sphaericus Pen-V no data outside [16] Fusarium sp. Pen-V no data outside [17] Class II PA-G E. coli Pen-G, Pen-X yes inside [18] Bacillus megaterium Pen-G, Cephalexin, Cephaloglycine, Cephaloridine no data outside [19] Alcaligenes faecalis Pen-G no data inside [20] Providencia rettgeri Pen-G no data inside [21] Class III Amp-PA Pseudomonas melanogenum Amp, Cephaloglycine, Cephadrine, Cephalexin no data inside [22] * Amp - ampicillin, Pen-G - penicillin G, Pen-V - penicillin V, Pen-K - penicillin K, Pen-X - penicillin X Another pathway of protein secretion is the Tat-sys-tem (twin arginine translocation). This mechanism is considered to mediate the transport of folded proteins with bound cofactors across the membrane. Evidently, the Tat-system and Sec-system work independently. In Tat-mediated transport, it is necessary for the signal peptide sequence to include the SRRXFLK motif, which contains two arginine residues [29]. The sequence of the signal peptide in the EcPA precursor contains 2 arginines separated by an asparagine residue (Fig. 2). Some literature data indicate that such a signal peptide can provide Tat-mediated enzyme processing. More recent data directly show that the E.coli signal peptide accounts for the enzyme translocation by the Tat-sys-tem [30]. PA from Alcaligenes faecalis is transported via the Sec-system [31]. Experiments on PA protein precursors lacking the signal peptide show that the inter-subunit spacer is initially cleaved at the N-terminus of the P-subunit, which, as a result, yields a free P-subunit and a polypeptide consisting of the a-subunit and the spacer [23]. Spacer cleavage occurs similarly in two stages in the course of PA maturation in an intracellular medium [23]. The authors of [23] demonstrated that spacer cleavage from the N-terminus of the P-subunit could take place only in the periplasmic compartment, while spacer removal from the C-terminus of the a-subunit can also take place in cytoplasm. At the same time, work [26] revealed that, at the very beginning, the a-subunit acquires a folded structure before beginning to function as a template for the correct folding of the P-subunit. Later, it was shown that spacer cleavage is an autocatalytic process [25]. Amino acid residues Lys299 and Thr263 of the inactive precursor were shown to play the primary role in the correct folding of the enzyme. Amino acid substitutions in these positions lead to a decreased yield of the active enzyme and accumulation of the inactive precursor [25, 32]. In summing up the available data, it is important to note that all stages of PA-G processing play an important role in the production of an active and soluble protein. The introduction of amino acid substitutions can affect any steps in protein processing; therefore, the production of active forms of novel mutant enzymes requires a careful selection of appropriate conditions for cultivation. EXPRESSION OF RECOMBINANT PAs iN E.coli Depending on the purposes being pursued, cloning and expression of recombinant enzymes can be performed in various systems; for example, bacteria [33-36], yeast [37-40], plants [41-43], insect cells [44-47], or cell-free systems [48-51]. Since PA-G is found only in bacteria, E.coli-based expression systems are considered to be the most appropriate for recombinant enzyme production. Below, we will discuss various approaches of PA-G expression in E.coli cells. Selection of promoter and expression vector Table 2. Cultivation conditions and their influence on yields of recombinant PA's Enzyme source Producing strain Promo- Antibiotics Inductor T, °C Medium Additives Enzyme yield Reference Orga nism Strain ter resistance E. coli JM109 trc IPTG/ arabinose 30 LB 112 U/VA^ 193 U/L/A™ [66] E. coli JM109 BL21 HB101 T7 Kn arabinose 30 LB glycerol 330 U/L /^ 820U/L, 440 u/L /^ 690 U/L [63] E. coli GM48 HB101 T7 Trc Kn IPTG 30 LB 84 U/L /A600 [32] E. coli MC1000 lacZ Kn IPTG 28 M9 PAA 14-650 U/g [67] E. coli DH5a tac lacI CmR IPTG [68] E. coli x6212 trc IPTG 1000U/L , 700 U/g [69] E. coli E. coli JM101, JM103, JM105 lac Kn IPTG galactose M9 glucose, galactose, glucose+ galactose 20-800U/L [70] E. coli SecB- chaperone 40-126 U/L/A600 [28] E. coli Cm IPTG 28 M9 Ca2+ 1 g/L 1700U/g [31] E. coli trc T7 araB Kn Cm IPTG, arabinose degP- chaperone PA: 20-800 U/L PA: 10450 U/L [65] E. coli BL21 (DE3) T7 [60, 71] E. coli HB101, JM109, MC4100 araB Cm Kn Amp degP- chaperone 14-470U/L, 570 U/L /A600 [60] E. coli Cm IPTG M9 Ca2+ 2.3 g/L , 14000 U/g (AfPA) [31] A. faeca-lis E. coli HB101 1000 U, 23 mg/L [20] E. coli JM109 rhaBAD Amp rhamnose M9 LB glucose, proline 4500U/L, 0.96 U/mg [72] E. coli JM109 (DE3) T7 Kn IPTG LB (200-270)* 103 U/L [21] K. citrophila E. coli BL21 (DE3) T7 Kn IPTG YE TH M9 MR 13460 U/L 1190 U/L /A600 28056 U/L 1576 U/L/A„00 [60] A substantial amount of information on homo- and het-erological PA expression in E.coli can be found in the literature. In terms of choosing an expression vector, both high- and low-copy number plasmids have been used. The following promoters have been applied for control of protein expression: lac, tac, trc, T7 and araB. PA-G genes were cloned from E. coli [52, 53], Actinomyces viscosus [54], Providencia rettgeri [55], Kluyvera citrophila [56], Bacillus megaterium [35, 57], and A. fa-ecalis [20]. The influence of the promoter type on the PA yield is shown in Table 2. There is no strong correlation between the type of promoter and the yield of the active enzyme. As a rule, stronger promoters (e.g. promoter of a T7 phage RNA-polymerase) provided higher levels o STQ TV e|l ----KD FVKF KDI R NYWPDAI AQ 107 . FV . T Av. PGEQDV Y. .Y MQV Q .FT.AS. R. 109 GNE .IF ---EEY VT.D 2SR D G.SDQE. KM 108 IGH RL .1. ----EA TLQT . FL T LGVAR.A HA 124 IGS RL .Bf ----SS Q. DT RYL T MG.ARVA QE 135 .VL E . I ----IE RLP. IQT A MFDHAD. S . 103 VGA RL ----RA ALEQ RFL T FGFYR.A SA 125 VG. RL .1. ----EA TLPQ RFL T WGFYR.A .A 129 NDTW HLFYj DSHY G.Y. KNKK D.Y! TTET DAIF( ANSH D. D.VH G.Y, ■R A.EH D. .F{ |r§atlk d. .f|jq E.coli A.faecalis B.bac/ius C.aggregan N.puncfifo P.denifrif R.xylanoph T.fhermoph -MKNRNRMIV NCVTASLMYY WSLP--MQKGLVRT GVAA.G.ILG LAW- -A-LAEQSSS EIKIV -.P.HAQVQ SVE ---------------------MKKRWLMM IMIVFA.VLP QNFT-------F. KEQKKVE NVT ---------- _MRLLKRIAG WIAVDIALVL VLGSSGGYLW LRQS-LAQTR GEIRVAGI.G SVT MPQPAQIKSF RKRWFPRILK RSLIVLLVLG LLLVGLAT.T VRQS-FPQES GTIQLP.LKA .VT ---------------------MS.SLLGR LLLS.G.SVL VAC.-------...D---T QVE ---------- -MHRGLRWAG FAAAALVALL AAASCGGYL. LR.STSPQTN GTLEL.GLRR PAE ------MLFP TMKRFLRGLV WLLGLFLFLA LLLGF.GYL. LRAS-LPQGE GRIAL.GL.A PVE 108 IA A] Isp DMS ILQG AD MN AWIDKVN-T NPETLLPKQF NTFGFT KRW EPFDVAMIFV GTMANRFSDS 110 ... .K ERD .FR. Y. .Y0EQ.R-R R. . -. . . .EY VD .D.Q EPL TD...V..W. .S.......T 109 LNG DG TKQ LIEQ .E IT VYgNEAVK- DQDKK.S.E. HDYR.L RK. KAT..VRLYM VS.T-Y.M.N 125 L.M !dr TIT . .EA .A V. .FgAINP-V L.PEF.IL- ---.VQ EP. Q . I.SLVWAK MVAWDLGGNW 136 .QEINA MKA Y .EA S . V. .YHKEHQGNA LSLEYAVLK. LNP.YK EP. QILHSLTWGK VMAYDLGTNF 104 .E.l |A. ERD . .R. .A F. L.I.R.L-A D.AK.M.R.. .D...K R. . TE......Y. . . . .G. . .GY 126 YRS F- GRA AVDA VA V. .YBRTDP-G L.LEFRLL- ---.YE EP. R.A..LVWAK MMSFDLSANY 130 ygk| k- EKE AVDA .A V. .FgASGA-P L.PEFRLL- ---. .R EP. TGP..LVWAK MMSYDLSGNW TT |ljAVQESNYPL KFNQQNSQTA ALLPRYDLPA 245 PAP------AAERKPQAQ. GTQN------234 QPDDQTEAK .DGKTSI.PL SSAVID--------241 PEGMPTSAP SPISGQ.TPL Q------------------240 PEFQKGKTG EDENSDETQF TAFGI----------262 PE--------GG.YQRK. G . A.------22 6 PE----------GGGASPQ .---------232 ----------EDLKLPL K---------236 Idnlall talkdkygvs QGMAVFNQ TA..MR QS.EKQH.PE R.R.L.DE K.AEI. AR.ERT..KE KAAKM.ED RRSL.I AQ-VGAED- -----ADF ERAI. . KT-LTPTQ------VEE G.AKT. AE.EAQF.PE KARVL.D. ERYR.R ARGLEPPR------IAE KRHR. . ARGVSPKR------LLE E.coli A.faecalis B.badius C.aggregan N.puncfifo P.denifrif R.xylanoph T.fhermoph K WLVNPSA L .INDTT. .KNDLE. M PAFT.DG PPYPQDL F .NED.L. M PPYPEDG PPYPED. GVISWG S # AGFG DV I -AERLSAE 374 . -PQ V. M -Q.K.NPA 350 . . Y. VT -E...NPA 352 NTSP VQ L -I..ID.- 350 NVLS VK L -I.KINPK 379 . . PR VN Y -RLE.NP. 335 NVGA VQ L VL.EARD- 337 NVGA VE L LL.EVE- 339 F WYA AYT sigI Ihgag- -----YDVT NTPF YPGLV . .N ... ....- -----F. .V . . IjVL V FV. GFL EV.P *.SP.- -----F. ME SGFI . . FIM L LRI SIW LAHIT.D- ----AINAI A. FP L.AV. L VQI SIW EV.I 1. CISK SAECP.N.. FSFA MI .VI NFN S .V s.. -----F.L. V.NVL L LGV PLW LAH KSP- ----TLEAV A.LP V. .V. L LQ. SLW lma| |eap- ----GLRAI A. LP L. .V. E.coli 246 PMLDRPAKGA DGALLALTAG KNRETIVAQF AQG----GAN GLAGYPTT A.faecalis 234 -.AHVSS--------------QVLA.EL ERQDKHW.GR . PDFA.KA B.badius 241---------------------ASKKIVKE REEFVQSSEE LGLPLKIG C.aggregan 240 ---------------------PT.AR.M. DLWATVYQTT . . GDQLAG N.puncfifo 262 ---------------------E.V.ESIT KPMMALEQLI .PT.IGIG P.denifrif 226 ---SE.GR----------------FAELL HA.----.LP .DDDR.RA R.xylanoph 232 ---------------------ERQAE.LL RLRRSLPVS------LEA T.fhermoph 236 ---------------------. . EAPSAL -LRMAPPRF------MEA MWVIGKSKAQ D L.STRPERV. AMIV.AK.SK N. . . .G.RTA N. . .SGELTD L.IA.PQ.TT N..VSGRRTE N..VAG.RTE E.coli 375 KPGYYLHNGK WVKMLSRE T IT KN----G QAETFTVWR VH NILQTD- -------------QTTQTAY ksSawdgke VASLL WTHQ MK KNWQ WT QQAAKQALT- I wyI Bi vhtIay D QSGHDPR 495 A.faecalis 351 RADQ.WF.NA .RT.EQ.K R -Q RG----Q ADREM. I . . P M.F.- -------------YEQG. . . .kIs...Y. .Q. . . . LNV A. R. .T FL D..S.M.IS- Ikh Hi .spIfl Q PADQ.I. 471 B.badius 353 N.AQ.FYK.. .RN.EK.T FI RGENGKA KKVEKVFFH P ISME- -------------KEKNV.. ..fflSFR.TG AQ. IQ YMKA NW . SLK FQ .A.SEFTMS- L Ikk hi y.vSk. I SNQI.D. 477 C.aggregan 350 -QN.VEY.NT REPVTVIN I .K .G----A EPI.L. .RV R. P ISDV- ---------- -RDDINE.-L frItalddd D.T.R FLNI NR R. .D FV AALRDYKAPM Q Fvi I.D hi yaaI.v I RN.D-G. 471 N.puncfifo 380 N.NQ.EV... ..D.KLVQ • Q AG----S .PIVQ. .RY R. P . SDVS PNLKKFQASQ PLEIPQNY.V LRHTALEP- SKLGY IPQI NR Q. • - FR TA.SNYDVPA Q Lvi I.D HI qmpIkf I ak.n-g. 513 P.denifrif 336 N.RQ.RAHDG .KE.TA.R FR • G----Q PEVET. . .E EY V G. I . - -------------PG. A. . . FnI..K.Q. IST.K . VDS T. Q. YE .L D. .E.V.T.- Ird Hi .spJhv V AE . .Q. 456 R.xylanoph 337 -GRG.RYR.E VRPYRV.. R .E GD----. EDV.LR .RE . Y P VSGV- ---------- -VDAPGARPL LRHTSLEP. DRTIE FLGV NR GG.E FN EALRLYKAPS Q Fvi Bee hi .apIkf V RE. SGL 460 T.fhermoph 339 -GRG.RYK.R V.PYGV.. V .R .G----. RE.VLK .RE .Y P ITDA- ---------- -LEDPPK.PM LRfVSLDE. DHI. K FLGV NR G. .E FK KALLPYSAPS Q FV§ |.E 11 IAP0KF V KE. TGM 462 REVIEWS E.coli 496 L vpg-tgkw D K LLPFEM N KVYl Iqsg y[ ANWl ISPQ KDYPASDLFA FL GGAD VT A.faecalis 472 V AK.-D.SM V 2 IKS.DA I A 1 Ipq. .J V.. Bk. a P.-KTNTDT YY TYG. MN B.badius 478 F T..-..EY E FQS.SK QAll Ikk . . | V.. Ik. a .YW-RNGEYS IV . KDN • Q C.aggregan 472 . . .W DAY E I YV...E L hiaI IsKD .1 VTA^ ERVI G.D-YPY.LG TS AAPF AQ N.puncfifo 514 Y ...W.DEY E 2 YID..K L . sf| Isq. I .T^J Ilvm RK-YPY.IT AD VYGY AQ P.denifrif 457 AR-P..D 3 VR..AD A - g -1 Isq. wl ... Irsa RG-D.ANFE. TP .S. . .V R.xylanoph 461 A . . . -D.R. E SV...S W ralI Ire . f| VTA^ ■kav P.S-YPYRIS LE AEPY AE T.fhermoph 463 V ...-N.E. L YRRP.E W Qaf| |ar. .| vta| (kvt pkg-fpyalt YD AEPY AE EIDRLLEQKP R-LTAD|AWD VIRQTSRQDp .LTSQYQD.D L-HSVq|i.G FNKKA.YS. QFINGM.ARD K-VDLNgLNE INYTA.FAQ R.IE.I.. GD K-..V.1MRA MLSDW-R.VEMIS.QT EPISLEiVQQ IQGDDR-N ..MAR.DARE K-..P.1I.. IN.EI.FL. R.R.MILSAG .-.GVKiMVR IQQDRR-S R.EE..LA.E K-.SLE|MKA IQQDQK-S JQ AATSGL-TQS E KLAQS.-PAN I KTLKKYQSEN * NV.P----TE . SI.V----DT FIL D.AE.I-DPQ VIE DLGP----LG VgE LL.P----L. ■GINLLN DDGKTWQQPG 632 1.-MEH .QAGQNAG.A 60 4 JNLKEDK NNDGYYDAGV 614 ---- -AMNGESAA 596 |L------QLGMTSSA 638 J.QQIRA E..RATTS-A 590 ---- -DARPGSRE 584 ---- -TMAPGSEE 586 NLRLFL .W.Y.R RTHY.K QA.EL .AQTLV .A.Y.. LFED.R LY.D.R DPRRQLVET .AGQAALT. KEYAY...Q PRETVAL PRLQAAQKL SQ.AE...1 PRA..WR.R EGA.AWRDR E.coli A.faecalis B.badius C.aggregan N.puncfifo P.denifrif R.xylanoph T.fhermoph E.coli A.faecalis B.badius C.aggregan N.puncfifo P.denifrif R.xylanoph T.fhermoph 633 605 615 597 639 591 585 587 MLKRTWAAV P-MPFDK--- ---WYSASGY ETTQDGPTGS LNISVGAKIL YEAVQGDKSP IPQAVDLFAG KPQQ---EVV LAALEDTWET LSKRYGNN-V SNWKTPAMAL TFRANNFFGV PQAAAEETRH 761 .Y.QVLMPV. .-ESHRA--- ---M..QT.F A.Q.GPNP.. I.L.M.T.V. LR.LALEAH. D.KR.NV.GE RSS.---.TM HT..QNAQAR ..QEQ.AQ-M ER.TM.TSVH R.SDK..T.T ..TTSGN.FA 733 AHNKLFNDSL NTVSDLT--- ---------- ---------- -REITDHRM GATLAYKVLS GEPTNYQWKT .EEA---.KI ILDSANEALA KLHEEKGTAA DQ.RM.IKTM ..G.KSLIAI .HG-YGSKT 724 A.EAVFADEL RGFFT.VYRL QNNFPALALR SVLLG.HDEW CDNVTTPD.V EDCPTTLAQA LRKGLATM.T LQGENDPTRW RWDRVHQAIF PHNPFSQ--- VEALRGFFER RVPTGGDTFT INVGPVRI.E 733 L..D.FHDQL .ERY.PN----GGDRWYAW ANLVKQ.NS. WWDNRNTPKV ENRDEILRQS FTE. . .ELER IQSK-DPKNW NWGKLH.VTF RNATL.KSG. APIESLFNRG A.ATAGNGET VN.NRWRANK 773 .VEDVLRDDN .AI.PAI--- ---L.NR--- ---------------------..RT.QM. HN.LL.ERAG V..TH.F.N. ADEAGRK.II ..S.DKAAAR .AD.FCSQEP AD.RIEIKQH V.ETS.YL.I ...GED.V.A 709 E.T.LPARE. GRRYW.E--- ----PRYLLR AMRRG-DR. CRP---SGGR GDCLRFAARA LER.LER-L. EEVP------ EWGAAHRAVF EHPVLSR--- TPLAR-FAGR EVA.GGDAYT VNVGPYDP-A 699 E.T.LPQRE. GEAYW.E--- ----PRYLLK ALKEG-DKN CDQPE-TEYR ESCLDYAALA LER.L.RKEA LGAR------ AWGEVHRARF PHAVLTH--- TPL.R-LSDR EVAFGGDRYT VNVGPFDP-E 704 SAILNVWLTS RVLFKT..EE A.FFDE.WNN A.VYQSYYYA A.LFE.FWKH VGLFQA..DV A. LFEA.Y-T ALVFAL.Y-T FIA PDGTVDKi Se Q KMYENFG RKSLWLTKQD VEAHKESQEV HVQR- 846 .TD rn.vrspI I .L. ..E C.TMDV.HT. IRRNAQ.STM LI.PQP 816 . .H K...LSdI 1 SL.a.wk F.PFLFD.K. .KRAAV.VSE NTGK- 805 NV- ----LSSi Is F glwqrge DIPMRFDAEV DGE----RL. RPTP- 804 HA- ----fhtI r M dswr.ie YHQMLSQQRN .TDNTAATLK IPKLGE 850 . S .s.easpI AL..G.D CRPQA..RDE ...VAV.R.T A.P.- 790 SP- ----lsg! Sd L GLWSGG. YLRMRTAGYE ADD----ALT RPA. - 770 HF- ----lsr| |a L plwqrgd YLPMR-FGAP LGR----TLL EPLPSP 776 I 'tH 1 >m| NDMIVFSPTT SDRPVLAWDV VAP| .NRlA.D-------AKS.EFC.A MP. .HY EMT.- -KQPEGFN. TP RQI DL.----NLANSRFM HTT| RMI DLG-------KLDNSVAI HT. .NR T.R-------EGKAEFCA. TP. RQV DL.----PEGRSLY. IPI RQI DL.----DMEGSLF. HPI 7 62 QAEYQNRG E 734 FTG... 725 EIIEM. 734 PYLQY.GP 774 SF.VTDIP 710 IGTSM. 700 SFRMDSGP 705 TLAMGHGP Fig. 2. Alignment of amino acid sequences of penicillin acylases G from different sources. Catalytic (3Ser1 residue and residues from the oxyanion hole are marked by and "#", respectively. Sequences of the signal peptide and intersubunit spacer are underlined in bold italic, and underlined, respectively. leads to abnormal protein folding and accumulation of an insoluble enzyme as the so-called inclusion bodies. The yield of the soluble protein can be increased by using less strong promoters. Generally, expression of each individual enzyme requires selecting an optimal vector. Factors that affect the level of PA expression are transcription and translation [53]. The limiting stage depends on the selected vector and the host strain. Nevertheless, most researchers choose strong promoters, such as tac and T7, and isopropyl-P-D-thiogalactoside (IPTG) is used as inducer. The yield of the soluble native protein is usually increased through the optimization of cultivation parameters. Influence of the temperature Work [58] revealed that the yield of active PA strongly depends on the temperature of cultivation. The experiments on protein expression were carried out at three different temperatures: 22, 28, and 37oC. For all combinations of plasmids and host strains, the highest yield of the native protein was observed at 22°C. This effect is probably explained by the fact that, at a low temperature, the enzyme undergoes successfully all stages of posttranslational modification and acquires the native conformation, which leads to an increase in the yield of the soluble active enzyme. An increase in temperature causes an increase in the rate of protein synthesis; therefore, the insoluble enzyme is accumulated in the cytoplasm. Influence of the medium composition and various additives Numerous studies have shown that the composition of the cultivation medium strongly affects the level of expression and the yield of the active enzyme. Work [59] showed that the highest yield of active PA-G is achieved when the minimal medium M9 is used with glucose as a carbon source. This approach allows to increase the portion of the periplasmic enzyme nearly 100-fold, relative to the intracellular enzyme. High enzyme yields were also achieved using the richest medium, YE, of all those studied (YE, TH, MR, M9), as described in [60]. One of the key parameters of PA expression is the presence of calcium ions in the cultivation medium. Ca2+ is important both for cellular growth [61] and for the formation of active soluble PA, since calcium ions are present in molecules of active PA [24, 60]. According to some authors, Ca2+ plays an important role in the translocation of the protein precursor across the membrane, as well as in the correct folding and maturation of the enzyme in the periplasm [31]. Another approach that allows to increase the level of soluble PPA in the cell is adding low-molecular carbon sources into the medium. It has been shown that additional carbon sources allow to increase the biomass, as well as diminish the accumulation of the insoluble protein in the cell [62]. The most common low-molecular carbon-containing compounds are lactose, glucose, arabinose, and glycerol. Works [62, 63] showed that the addition of glycerol reduces the level of the insoluble protein in the periplasm. Some authors consider glycerol as not only a carbon source, but also a “chemical chaperone” that facilitates protein folding and maturation. Regulation of the posttranslational modification Work [59] focuses on selecting the optimal strain for expression and optimization of medium compositions, as well as modifying the PA translocation system by means of alteration of the signal peptides structure. As it was previously discussed, the signal peptide of EcPA is responsible for the translocation of the precursor by the Tat-system [31]. However, as is known from the literature, Sec-mediated protein transfer occurs more rapidly [64]. The alteration of the translocating system allowed a substantial increase in the level of the soluble protein in the periplasmic fraction. The use of chaperons for correct PA folding An additional, actively developing approach that has emerged over the past decade is the use of chaperones for the optimization of protein expression. In case of PA, most researchers used degP chaperones or the chaperones of the Sec-system, if they participate in the intracellular transport of the enzyme [65]. This approach helps to achieve a many-fold increase in the yield of the active enzyme. In summary, it should be noted that PA-G expression depends on numerous factors. To create a strain for PA overexpression, one should be well aware of the details of limiting stages of expression, which are specific for each organism and expression system. The yield of the active enzyme can be improved if proteinases-lacking strains or strains with an altered translocation system are used. PA-G STRUCTURE Primary structure of PA-G At present, databases (GeneBank, EMBL) contain full nucleotide and amino acid sequences of PA-Gs from 40 organisms. Figure 2 shows the alignment of amino acid sequences of PA-Gs from different sources. In order to show comparison, the most distant enzymes are presented. The primary structure of E.coli PA is given as a full-length amino acid sequence, whereas for the -H. marismortui I-P. denitrificans I-A. faecalis I-S. wittichii l-S. proteamaculans '- |- A. xylosoxidans _ - I-P. rettgeri i- S. boydii I- E. coli I-A. baumanii I-Sphingomonas_sp. r |- O. iheyensis I |-V. eiseniae L I-R. pickettii I-R. biformata '-B. mallei 1--|- T. thermophilus I- R. xylanophilus I-G. violaceus I-C. aurantiacus |_I-R. castenholzii I-C. aggregans I-N. punctiforme -- B. weihenstephanensis B. thuringiensis I- B. cereus I-B. megaterium '-B. badius Fig. 3. Phylogenetic tree of penicillin acylases G. Quaternary structure of PA-G. The first 3D structure of the PA-G molecule was determined in 1995 for a PA from E. coli with a resolution of 1.9 A (PDB 1PNK) [24] (Fig. 4). The active enzyme is a heterodimer with a molecular mass of 86 kDa. It consists of a smaller a-subunit (24 kDa) and a bigger P-subunit (62 kDa). At the N-terminus of the P-subunit, there is the Ser catalytic residue (marked red in Fig. 4). The average dimensions of the heterodimer are 70 x 50 x 55 A. The polypeptide chains of the two subunits form a pyramid-like structure with a deep bowl-like cavity in the middle, with the active site located on its bottom. Like all Ntn-hydrolases, PA-G contains the characteristic motif aPPa [73]. PA has one aPPa - domain which consists of a- and P-subunits [24], and the domain is one of the biggest aPPa ones among all known Ntn-hydro-lases [73]. In terms of the structure, the protein globule can be divided into three regions - A, B, and C. Region C includes eight elements of a secondary structure conserved in all representatives of Ntn-hydrolases. These elements form three antiparallel layers of four aPPa-motifs, each. Regions A and B consist of similar elements of a secondary structure whose spatial arrangement is quite the same in all representatives of Ntn-hydrolases. However, these regions might occupy different positions in polypeptide chains of various Ntn-hydrolases. For example, in the PA-G molecule, regions A, B, and C are arranged in the following order: C-B-A. other enzymes only the differing residues are shown. Well-conserved residues are marked by dark gray, and similar residues are given in light gray. Fig. 4. Structure of the active heterodimer of PA-G from E.coli (PDB 1PNK) [24]. a- and P-subunits are shown in yellow and dark blue, respectively. Catalytic PSerl residue and Ca2+ ion are shown in red and green, respectively. As is seen in the figure, the signal peptide region contains no conserved residues or consensus sequences. They all differ not only in the amino acid sequence but also in length. Intra-subunit spacers differ as well and do not have conserved amino acids in their sequences. The sequences shown in Fig. 2 contain two important conserved amino acid motifs: (D/E)RXXQ(M/L) (E/D) in the a-subunit and NXXYADXXGNI(G/A)Y in the P-subunit. Apart from these two regions, there are some well-conserved residues, e.g., first and second residues in the P-subunit are serine, which is important for catalysis and neighborous asparagine. The total amount of highly conserved residues in PA- sequences does not exceed 7%. Figure 3 shows the phylogenetic tree of PA-Gs. As is seen, most of these enzymes occur in proteobacteria. Fig. 5. Structure of the active heterodimer of PA-G from A .faecalis (PDB 3K3W). a- and P-subunits are shown in yellow and dark blue, respectively. Catalytic PSerl residue and Ca2+ ion are shown in red and green, respectively. Disulfide bond in P-subunit between residues Cys492 and Cys525 in wild-type enzyme is shown in magenta. Insert in right part of figure shows fixation of N-terminus of a-subunit and C-terminus of P-subunit due to creation of new disulfide bond (shown in orange) after double mutation aQ3C/PP751C. Fig. 6. Main amino acid residues in the active site of PA from E. coli (structure PDB 1AI4). Catalytic PSerl residue and residue PGln23 are shown in red and orange, respectively. Residues from oxyanion hole are presented in magenta. Residues from substrate-binding domain are shown in green and yellow for subdomains S1 and S2, respectively. Residue aPhe146 belonging to both subdomains is in blue. At the end of 2009, the 3D structure of recombinant PA from A. faecalis (AfPA) expressed in E.coli cells was deposited into the protein data bank (PDB), although this enzyme was isolated and described early in the 1990s. In May 2010, the second structure of AfPA obtained from orthorhombic crystals appeared in the PDB (PDB 3ML0). AfPA is of particular interest due to high thermal stability compared to one for all known penicillin acylases G. An analysis of the AfPA structure revealed that the elevated thermal stability is associated with the presence of a disulfide bond between Cys492 and Cys525 in the P-subunit (marked pink in Fig. 5), which are absent in EcPA. The structures of AfPA and EcPA share a high spatial homology. A computer superposition of the structures of these two enzymes shows high spatial homology in the organization of their polypeptide chains, especially in the region of the active site. Some minor deviations are observed only in the outer regions of the enzyme molecule. It should be noted that both AfPA structures have a resolution only of 3.3 and 3.5 A for PDB3K3W. ENT and PDB3ML0.ENT, respectively. This resolution is considered low in modern X-ray crystallography and does not allow to determine exactly the spatial arrangement and interactions of residues in the active site, which is important for understanding catalytic mechanism. STRUCTURE OF EcPA's ACTIVE SITE Structure of the catalytic domain The early studies of PA revealed the key role played by a Ser residue in catalysis. Covalent modification of this residue by phenylmethylsulfonylfluoride (PMSF) was shown to lead to the full loss of the enzyme activity [74]. X-ray diffraction data on PA covalently modified with PMSF (PDB 1PNM) [18] allowed to determine that the catalytically important residue is the N-terminal serine of the P-chain. It is worth noting that in the vicinity of PSer1 there are no imidazole or carboxyl groups that participate in the catalytic processes of acylation and deacylation by means of relay proton transfer and are usually found in active sites of serine proteases. Therefore, PAs were classified as so-called hydrolases with the N-terminal nucleophile, or Ntn-class [75]. Based on the structural data obtained on EcPA, a model of the catalytic mechanism of Ntn-hydrolases was proposed in 1995. N-terminal serine PSer1 functions as a nucleophile (marked red in Fig. 6). Residue PGln23 (shown in red in Fig. 6), which is positioned close to PSer1, improves the nucleophilic properties of the catalytic serine. During the reaction, the covalent intermediate is formed trough a transition state, which is stabilized by a so-called oxianionic hole. The hole is formed by residues PAsn242 and PAla69 (marked pink in Fig. 6). A comparison of the amino acid sequences of PA-Gs from different sources (Fig. 3) reveals that residue PAsn242 is highly conserved in all mentioned enzymes, while residue PAla69 occurs only in the half sequences presented and Asp residue is present in this position in other enzymes. Structure of the substrate-binding domain The substrate-binding domain of the active site consists of two subdomains - S1 and S2. Subdomain S1 is responsible for interacting with the acyle part of the substrate. It exhibits high binding specificity and consists basically of hydrophobic residues. The “closed” structure of this domain, as well as its high hydropho-bicity, makes the enzyme very selective for benzene rings with small radicals at Ca-atoms or aromatic rings. The main residues which form the “closed” structure of the S1 subdomain are aMet142, aPhe146, PPhe24, PPhe57, PTrp154, PIle177, and PSer67 (marked green in Fig. 6) and also PPro22, PGln23, PVal56, PThr68, PPhe71, PLeu253, and PPhe256 (not shown in Fig. 6). As is seen, only two residues are located in the a-subunit, while most of the residues that are essential for binding the acyl part of substrate are located in the P-subunit. The sterically limited hydrophobic cavity in the “open” state has a thermodynamically unfavorable contact with the solvent. Hydrophobic interactions between the substrate and the enzyme result in a double energy gain due to, first, the energy of transfer of a hydrophobic substrate into the enzyme hydrophobic cavity from the solvent and, second, due to the exclusion of water molecules from the active site. It is suggested that n-n interactions exist between the benzene rings of the phenylacetic acid (PAC) and PPhe24, which are located side by side. Residue aPhe146 is located at the opposite side of the hydrophobic pocket. It interacts with PAC and shields the active site from the solvent. Another phenylalanine residue, PPhe57, is located at the bottom of the hydrophobic cavity. The shortest distance between this residue and the inhibitor is 4.7 A, which is insufficient for a direct interaction. However, this residue may be essential for the proper overall structure maintenance of the substrate-binding site, since it is located close to PPro22 and PPhe24 (the distances are 3.5 and 3.9 A, respectively), which directly participate in substrate binding. The second subdomain of the substrate-binding site (S2) is responsible for the binding of the nucleophilic part. This subdomain represents the bottom of the bowl-like cavity in the middle of the molecule and accounts for the enzyme’s quite broad specificity for the nucleophilic part. Besides, this domain is enantioselec-tive, which allows to use the enzyme for kinetic separation of the optical isomers of amines. Domain S2 consists of the following residues: aArg145, aPhe146, PPhe71, and PArg263 (marked yellow in Fig. 6) [76-80]. According to the analysis of the structure of the EcPA inactive mutant PAsn241Ala complex with penicillin [79], at the first stage the antibiotic binds in the “open” conformation, which allows the bulky amide part of the substrate to enter the enzyme’s active site. In the “open” conformation the PPhe71 phenol ring becomes parallel to the substrate’s P-lactam ring. Moreover, substrate sorbtion results in Van-der-Waals interactions between the methyl group of the penicillin molecule and C61-atoms of aPhe146, which also strengthens the bond. A complex of the native enzyme with a “slow” substrate penicillin G sulfoxide (PDB 1PNM) gives information about the enzyme’s structure in pre-catalytic act stage [78]. In this case, the positions of residues aArg145 and aPhe146 correspond to the “closed” conformation, and the amide group of PAsn241 forms a hydrogen bond with O-atom of the substrate’s carbonyl group. Results of site-directed mutagenesis of residues aArg145 and PArg263 show that both of them are essential for catalysis and PArg263 is also essential for autocatalytic maturation [77]. Structural and kinetic data indicate that PArg263 participates in the stabilization of the transition state, since its positive charge increases the polarity of the oxianionic hole. It should be noted that both PArg263 and aArg145 are highly conserved and present in PA-Gs of nearly all known sources (see Fig. 2). Another special feature of PA catalytic mechanism is that the active site can exist in “open” and “closed” conformations, as was shown in [80]. The authors resolved the structure of complexes of EcPA with various ligands. The “open” conformation is important for substrate binding, while effective catalysis requires protection of the active site from solvent molecules, which is achieved in the “closed conformation.” PA-G PROTEIN ENGINEERING In the past, the main approach to increasing the efficiency of industrial processes had been to optimize conditions in the biocatalytic process. Such optimization was based on kinetic parameters and the physicochemical properties of the reaction medium’s components. This approach was successful and led to some very good results. Today, the approach has practically exhausted its potential: actual design of the enzyme is becoming increasingly popular. X-ray diffraction studies on PA, its mutants, and complexes with different substrates have provided a prospective for understanding the structure-function relationship, as well as for rational design, of the active site. The purpose of this design is to improve the enzyme’s properties, which could increase the efficiency of PA-mediated synthesis of antibiotics and separation of enantiomers. Because of thermodynamic constraints, the synthesis of antibiotics is based not on direct condensation but on nucleophilic substitution. The minimal scheme of the process is given below: k-4 Scheme 1. A minimal scheme for half-synthetic P-lactam antibiotics preparation by nucleophilic substitution. E, S, and ES are the enzyme, substrate (donor of acyl moiety), and the enzyme-substrate complex, respectively. EA, Nu, and EANu are the acyl-enzyme, nucleophile, and the double complex of acyl and nucleophile. Ks, Kn and K - are binding constants of substrate free enzyme E, the nucleophile with acyl-enzyme EA, and the product with free enzyme E, respectively. Papers [81, 82] contain a detailed analysis of this scheme and its various derivatives. The basic result following from this analysis is that the description of the process’s efficiency cannot be accomplished by using such common parameters as catalytic constants, Michaelis constants, or constants of inhibition by the reaction products. The parameters a, P, and Y are used instead. Parameter a = (k 4/Kp)/(k2/Ks) describes the specificity of the enzyme for the product and initial acyl donor, parameter P = k4/(k3-Kn) reflects the maximum nucleophilic activity of acceptor, and Y = k5/k4 describes the ability of the triple complex EANu to undergo either synthetic or hydrolytic transformation (i.e., the ratio of the rates of synthesis and hydrolysis, S/H). Therefore, we shall use the above-mentioned parameters in estimations of the efficiency of PA engineering and in studies of PA mutant forms, as applied to antibiotic synthesis. Production of chimeric PAs by means of DNA shuffling At present protein engineering exploits a broad range of approaches based on the introduction of both directed and random amino acid substitutions, or even fragments of a polypeptide chain. One of these approaches, namely DNA shuffling, is now increasingly gaining in popularity and is successfully applied in the production of industri- Table 3. Synthetic efficiency of parent and hybrid PA (15 mM D-PGA, 25 mM 6-APC, pH 7.0) Enzyme a P, mM-1 Y Pmax, mM vPs % PA E. coli 7.8 78 0.14 2.2 100 PA K.cryocrescens 12.7 98 0.19 2.1 110 PA P.rettgeri 5.8 32 0.30 1.9 59 PA 6G8 11.1 130 0.12 2.6 149 PA 73C4 11.6 120 0.12 2.4 95 PA 6B11 6.4 115 0.13 2.5 115 ally significant enzymes with enhanced properties. This method is based on a recombination of genes coding for homological enzymes from various organisms, which results in the production of chimeric proteins that consist of fragments of original enzymes. DNA shuffling has been applied in engineering PAs from E. coli, K. cryocrescens, and P. rettgeri [83]. The extent of homology of these enzymes is equal to 77% (E. coli - K. cryocrescens), 61% (E. coli - P. rettgeri), and 61% (K. cryocrescens - P. rettgeri). Screening of 81 transformants revealed three chimeric enzymes that exhibited higher catalytic activity (vPs) as well as improved synthetic properties (see Table 3). It is noteworthy that in enzyme 6B11 all parameters were selectively improved. It was shown in an experiment that a decrease in a was caused by a two-fold increase in KP for ampicillin (the product), while in 73C4 an increase in a was caused by a two-fold increase in Ks for D-PGA. DNA sequencing showed that chimeric mutants 6B11 and 73C4 were obtained by inclusion of some parts of the PA gene from K. cryocrescens into that of E.coli. A certain number of random mutations that do not occur in the parent genomes and are located far from the active site were also described. However, these mutations can have a substantial effect on the enzyme’s properties. For example, the substitution of PGly385, which is positioned 13.5 A from the active site, by serine residue (PGly385Ser) in the hybrid 6G8 can affect the availability of the active site. To study the influence of such substitution on the catalytic properties of enzyme, the authors introduced the corresponding mutation into £cPA. The results were amazingly unpredictable: the authors reported a 22% increase in the maximum yield and a 80% increase in the S/H ratio compared to the wild type enzyme under the same conditions. The parameter a did not change. Similarly, random mutation of aAsp148Gly works in the same way, i.e. it results in a 20% increase in the maximum yield and an 80% increase in the S/H ratio. In the case of this amino acid change the observed effect can be explained by the fact that the aAsp148 is located at the base of the catalytic a-loop, which is responsible for the conformational transitions in the active site. As it was shown for residues aArg145 and aPhe146, any changes in this loop can lead to the alteration of both the substrate specificity and catalytic activity. Table 4. Catalytic efficiency of mutant EcPA in reactions of antibiotic synthesis [84] Enzyme Acyl donor Ampicillin Cephalexin a P, mM-1 1/Y a P, mM-1 1/Y PAS2 ®rA 13.2 0.5 6 7.3 0.5 59 ®rM 16.4 0.5 6 9.1 0.5 59 ^ J? 01 664 aR aP ®rA 218 6.3 364 58.8 18.4 69 ®rM 8.8 6.3 364 2.4 18.4 69 PF24A ®rA 209 10.2 286 .8 CO 8 21.5 154 ®rM 11.6 10.2 286 4.9 21.5 154 aR160P aF161A PF24A ®rA 200 4.9 167 57.2 21.1 58 ®rM 7.6 4.9 167 2.2 21.1 58 Thus, DNA shuffling can be employed not only as a tool in the production of enhanced versions of PA, but also as a promising approach to the design of site-directed mutations that are impossible to predict based on knowledge of the enzyme’s 3D structure. Combinatory saturating mutagenesis In work [84], saturating mutagenesis was combined with the introduction of random mutations and applied to residues aR160, aF161, and PF24, which were juxtaposed to the enzyme’s active site (single, double, as well as triple mutants were obtained). Different amino acid changes were introduced in these positions with degenerate primers, and a library of 700 various clones was obtained. HPLC-based screening was used to test mutants for their ampicillin synthetic activity. As a result, three mutants with improved catalytic properties were selected (Table 4). Moreover, one of the mutants (PF24A) also exhibited good catalytic properties in the reaction of cefalexin synthesis. It should be noted that the method of random mutagenesis has not found broad application, because of the absence of a simple mutant screening procedure. At the same time, directed mutagenesis has turned out to be the most popular method. RATIONALE DESIGN Acyl-binding domain Processes of preparation of P-lactam cores by hydrolysis of natural antibiotics will be more efficient in the case of reduced affinity of the enzyme to phenylacetic acid, which is a byproduct of the reaction and a competitive inhibitor of PA. A requirement for effective synthesis of half-synthetic unnatural antibiotics is a high specificity of the enzyme for the FAA derivatives carrying substitutions at C atom (D-phenylglycine, phenyglycolic acid, C -methyl-FAA). In case of natural PAs, the values of the Michaelis constants for FAA derivatives carrying substitutions at Ca are about 10-100 mM, which is 100-1,000 times higher than for FAA [85]. Therefore, production of mutant enzymes with low values of the Michaelis constant for FAA derivatives carrying substitutions at the C atom and high inhibition constants for FAA is of great interest. Paper [86] describes point mutations PPhe24Ala and aPhe146Tyr and their combination PPhe24Ala/ aPhe146Tyr meeting these requirements. For example, in case of mutant .EcPA PPhe24Ala, FAA inhibition was 18 times lower in comparison with the wild-type enzyme (Kp = 1.1 and 0.06 mM, respectively), but affinity to C -substituted FAA derivatives was 5 times ■j a higher. constructing the mutants, the authors suggested that substitution of the hydrophobic residue that forms the base of the acyl-binding domain could dramatically change the enzyme’s specificity for both C -substituted FAA derivatives and the natural sub- a strate. X-ray analysis of complexes of the mutants with FAA derivatives provided structural explanations of the observed phenomena. Removal of the aromatic ring in the mutant PF24A leads to structural perturbations in the active site. As a result, in this mutant FAA binds in the “open” conformation, as opposed to the wild-type enzyme in which FAA binds in the “closed” conformation. This, in its turn, results in the disappearance of hydrogen bonds between the carbonyl O-atom in FAA and residues PAla69 and PAsn241 that form the oxian-ionic hole. This explains the multi-fold increase in the value of the inhibition constant. Unlike FAA itself, its derivative Ca-methyl FAA binds in the “closed” conformation in the mutant EcPA PF24A. Simultaneously, Ca-CH3 takes the place of the removed phenyl group, which leads to a 10-fold increase in binding. Notably, the mutation of PPhe24 strongly affects the enzyme stereospecificity for (^)-isomers of C -substituted FAA derivatives. Therefore, PPhe24 can be a potential target for alteration of the enzyme enanti-oselectivity, which can be used for obtaining optically pure C -substituted FAA derivatives. Substitution of phenylalanine by tyrosine in the aF146Ymutant does not cause conformational rearrangements in the active site, which explains the FAA binding comparable to that in wild type EcPA. However, the van der Waals interactions between a Ca-group of FAA derivatives and OH-group of aTyr146 make binding more efficient. In work [87], the natural specificity of EcPA was altered from penicillini to cephalosporin C, which gave the opportunity to create a EcPA-based biocatalyst for preparation of 7-aminocephalosporinic acid directly form cephalosporine C. An alignment of the amino acid sequences of EcPA and cephalosporinacylase (CA) from P. diminuta was performed in order to determine the binding site for the aromatic hydrophobic acyl part of penicillin in PA and that for the linear hydrophilic (glu-taryl) acyl part of cephalosporin C in CA. As a result, seven residues from the hydrophobic pocket of EcPA were substituted by the corresponding residues from CA. The obtained mutant had a specificity for cephalosporin C 8-fold higher than wt-EcPA. Unfortunately, these results are of little practical use aside from scientific interest, since the activity of the prepared mutant enzyme was much lower than that of the native CA. Site-directed mutagenesis of the nucleophile-binding site Increasing the acyl part-binding properties is insufficient for improving the enzyme synthetic efficiency. For example, for mutant EcPA PPhe24Ala it was shown that increased D-phenylglycinamide binding leads to an increase in product (ampicillin) binding, which finally elevates parameter a. Interestingly, substitutions of residues PPhe24 and aPhe146, which are responsible for binding the acyl moiety, also account for a two-fold increase in the nucleophile properties of 6-APA. The fact that alterations of the protein structure in a particular region can cause structural rearrangements in adjacent regions does not contradict the basic principles of protein molecule organization. Mutations in the acyl-binding part (S1) could actually cause structural changes Table 5. Kinetic parameters for ampicillin synthesis for wild-type enzyme and mutant EcPA with substitution of aArg145 (15mM D-PGA, 25mM 6-APC, pH 7.0) Enzyme a (5 ,mM-1 Y P , max’ mM EcPA wild-type 7.7 80 0.14 2.2 EcPA aArg145Gly 29 420 0.04 3.6 EcPA aArg145Ser 14 350 0.05 3.3 EcPA aArg145Leu 15 280 0.06 2.8 in the nucleophile-binding site (S2) so long as residues PPhe24 and aPhe146 are located in the border region of S1 and S2 subdomains and these residues produce the hydrophobic neck of acyl-binding domain (Fig. 6). On the other hand, it is impossible to determine whether the increase in nucleophile binding (K ) or decrease in water reactivity (k3, k5) plays the key role. PPhe24Ala substitution could affect the spatial position of the neighboring PGlu23, which coordinates the deacylating water molecule and, therefore, decreases the rate of hydrolysis. However, using available data, it was shown that improving the enzyme nucleophilic specificity causes an increase in p: so the effects of point mutations in the nucleophile-binding site are rather predictable. In work [89], the authors achieved a substantial increase in parameter p by mutations of aArg145, which interacts with the ampicillin carboxylic group in the closed conformation and can affect 6-APA binding, according to X-ray analysis. In order to study all the possible effects of a substitution of aArg145, this residue was subjected to saturating mutagenesis. Preliminary results of ampicillin synthesis in diluted solutions showed that all 19 mutants have an increased ability to transfer an acyl group to 6-APA. Three of the most promising mutants of EcPA (aArg145Leu, aArg145Gly and aArg145Ser) were selected and subjected to a detailed kinetic study (table 5). The obtained results show that the removal of a positive charge in position a145 leads to a substantial increase in the nucleophilic properties of 6-APA. A nearly synchronized increase in a leads to the conclusion that elevated nucleophile binding (Kn, see the scheme above), expressed as an increase in p, inevitably results in higher affinity to the reaction product (Kp, see the scheme above), and it is impossible to improve both parameters simultaneously. However, the negative effects on a can be mitigated to some extent if ampicillin is removed from the reaction medium. According to X-ray diffraction data, the residue aPhe146 interacts with the methyl group of penicillin upon its binding in the open conformation and could affect the binding of the p-lactam ring of 6-APA. In order to clarify the role of this residue, saturation mutation analysis was also carried out. Preliminary studies of enzymatic ampicillin synthesis showed that all 19 mutants have an increased ability to transfer the acyl group to 6-APA, but the catalytic activity of all mutants decreases at least 10-fold, which did not allow the authors to study the synthetic abilities of the mutants in detail. Work [90] represents a good example of employing rational design for improving EcPA catalytic properties. The authors performed a structural analysis and molecular modeling of ligand binding in the active site of the enzyme. The results showed that mutation of PPhe71 alters the substrate’s orientation and increases the interaction of substrates with the oxianionic hole. Therefore, it would be reasonable to expect the mutation of PPhe71 to increase the PA catalytic activity and alter both the stereoselectivity and specificity of the enzyme for the leaving group. Four mutants with amino acid changes PPhe71Lys, PPhe71Glu, PPhe71Leu, and PPhe71Arg were prepared. Three of them showed improved catalytic properties, and two mutants had higher stereoselectivity in terms of separation of enantiomers; however, the effect of an introduction of a particular amino acid was quite opposite. For example, the PPhe71Leu mutant had the best catalytic properties in the antibiotics synthesis reactions, while its enentioselectivity was lower than that of the wild type enzyme. The most pronounced increase in enantioselectivity was observed for the mutant EcPA PPhe71Lysones for the mutant EcPA PPhe71Leu. Based on the obtained data, one made the conclusion that a simultaneous improvement of all basic catalytic properties of the enzyme seems to be impossible. Evidently, particular tasks could be solved only by individual fine-tuning of the enzyme based on the substrate’s structure. Obtaining a permutated enzyme Another approach to alter the enzyme’s properties is preparation of so-called permutated enzymes. As seen in Figs. 4 and 5, in PAs from E. coli and A. faecalis, the N-terminus of the a-subunit is placed in juxtaposition with the C-terminus of the P-subunit, which allows to obtain a permutated one-chain enzyme by linking both termini by a flexible spacer. Engineering such an enzyme would allow to obtain the recombinant protein directly in the cytoplasm without transportation of the precursor to the periplasmic compartment and cleavage of the inter-subunit spacer, since these stages were shown to be the main reasons of the low yield of the enzyme produced in available systems of PA-G expression. To this day, there is only one work that describes preparation of the permutated enzyme [91]. A random sequence of 4 amino acid residues was chosen as a linker between the subunits. A library of mutant clones carrying the gene of the permutated enzyme was created. Subsequent screening of the clones revealed 20 clones that produced the active enzyme; however, all the mutants were much less efficient in terms of specific activity as compared to the wild type enzyme. AfPA stabilization by formation of disulfide bonds As it was described earlier, PA from A. faecalis is one of the most thermostable penicillin acyllases known to this day [20], and this remarkable property is attributed to the presence of a disulfide bond in the P-subunit of AfPA (Fig. 5). Additional disulfide bonds were introduced into the enzyme’s globule in order to further stabilize the molecule [92]. Since 2006, when the experiments were performed, the structure of the enzyme has not been determined. The authors constructed a computer model using homology modeling based on the structure of EcPA. The search for possible sites of disulfide location was performed with the MODIP program. The computer analysis resulted in 32 possible variants of disulfide bonds in different positions. An additional analysis yielded two final variants - pairs of substitutions aQ3C/PP561C and aT52C/aY64C. The first pair of substitutions should lead to the formation of the covalent bond between the N-terminus of the a-subunit and the C-terminus of the P-subunit (see inset in Fig. 5), which is basically unstructured (Fig. 5). In the case of the second pair of amino acid changes, the disulfide bond should stabilize a loop that connects two a-helices. The analysis of the properties of the obtained mutants showed that introduction of the point mutations aGlu3Cys and PPro561Cys did not affect the rate of thermal inactivation, while in the case of the double substitution, the temperature at which the enzyme loses 50% of its activity after 20 minutes of incubation increased from 50oC to 53 oC. The second pair of substitutions did not affect the enzyme’s stability, which suggests that the stability of the two a-helices is not critical for the stability of the whole protein globule. This suggestion corroborates recent X-ray diffraction data, which show that the mentioned a-helices form additional contacts with the structural elements of the P-subunit. CONCLUSIONS Despite the large volume of work on the engineering of penicillin acylases, the problem of altering the catalytic properties and stability of PAs is far from being solved. The data presented show that the catalysis is affected by residues located at 15-20 A around the catalytic site of the enzyme. Therefore, a detailed investigation of the roles of amino acid residues located in the active site in catalysis and substrate specificity, as well as gaining insight into how they affect catalytic parameters, appears to be important for both biotechnology and fundamental science. It’s one’s hope that isolation and investigation of penicillin acylases from×

About the authors

V I Tishkov

Lomonosov Moscow State University; Bach Institute of Biochemistry, Russian Academy of Sciences; Innovations and High Technologies MSU Ltd

Email: vitishkov@gmail.com

S S Savin

Bach Institute of Biochemistry, Russian Academy of Sciences; Innovations and High Technologies MSU Ltd

A S Yasnaya

Bach Institute of Biochemistry, Russian Academy of Sciences; National Research Center "Kurchatovskii Institute"

References

- Sakaguchi K., Murao S. // J. Agr. Chem. S 1. oc. Japan. 1950. V. 23. P. 1-3.

- Claridge C.A., Luttinger J.R., Lein J. // Proc. Soc. Exp. Biol. Med. 1963. V. 113. P 1008-1012.

- Hamilton-Miller J.M. // Bacteriol. Rev. 1966. V. 30. P. 761-771.

- Valle F., Balbas P., Merino E., et al. // Trends Biochem. Sci. 1991. V. 16. P 36-40.

- Arroyo M., de la Mata I., Acebal C., et al. // Appl. Microbiol. Biotechnol. 2003. V. 60. P 507-514.

- Rajendhran J., Gunasekaran P // J. Biosci. Bioeng. 2004. V. 97. P. 1-13.

- Polderman-Tijmes J. J. Biochemical characterization of alpha-amino acid ester hydrolases. Ph.D. Thesis. Groningen: University of Groningen, 2004.

- Deshpande B.S., Ambedkar S.S., Sudhakaran V.K., et al. // World J. Microbiol. Biotechnol. 1994. V. 10. P. 129-138.

- Murao S. // J. Agr. Chem. Soc. Japan. 1955. V. 29. P 404407.

- Batchelor F.R., Doyle F.P, Nayler J.H.C., et al. // Nature. 1959. V. 183. P 257-259.

- Vanderhaeghe H. // Methods Enzymol. 1975. V. 43. P. 721-728.

- Shewale J.G., Deshpande B.S., Sudhakaran V.K., et al. // Process Biochem. Int. 1990. V. 25. P. 97-103.

- Shewale J.G., Sudhakaran V.K. // Enzyme Microb. Technol. 1997. V. 20. P 402-410.

- Bruggink A., Roos E.C., De Vroom E. // Org. Process. Res. Dev. 1998. V. 2. P. 128-133.

- Svyadas V.K., Klesov A.A, Nys P.S. // Antibiotiki (Antibiotics). 1976. V. 21. P 698-704

- Pundle A., SivaRaman H. // Curr. Microbiol. 1997. V. 34. P. 144-148.

- Sudhakaran V.K., Shewale J.G. // Hindustan Antibiot. Bull. 1995. V. 37. P. 9-15.

- Hewitt L., Kasche V., Lummer K., et al. // J. Mol. Biol. 2000. V. 302. P 887-898.

- Savidge T.A., Cole M. // Methods Enzymol. 1975. V. 43. P. 705-721.

- Verhaert R.M., Riemens A.M., van der Laan J.M. // Appl. Environ. Microbiol. 1997. V. 63 P. 3412-3418.

- Cheng T., Chen M., Zheng H. // Protein. Expr. Purif. 2006. V. 46. P 107-113.

- Kim D.J., Byun S.M. // Biochim. Biophys. Acta. 1990. V. 1040. P 12-18.

- Schumacher G., Sizmann D., Haug H 23.., et al. // Nucleic. Acids Res. 1986. V. 14. P. 5713-5727.

- Duggleby H.J., Tolley S.P, Hill C.P., et al. // Nature. 1995. V. 373. P 264-268.

- Kasche V., Lummer K., Nurk A., et al. // Biochim. Biophys. Acta. 1999. V. 1433. P. 76-86.

- Lindsay C.D., Pain R.H. // Eur. J. Biochem. 1990. V. 192. N 1. P. 133-141.

- Economou A. // FEBS Lett. 2000. V. 476. P. 18-21.

- Chou C.P., Tseng J.H., Kuo B.Y., et al. // Biotechnol. Prog. 1999. V. 15. P. 439-445.

- Berks B.C. // Mol. Microbiol. 1996. V. 22. P 393-404.

- Ignatova Z., Hornle C., Nurk A., et al. // Biochem. Biophys. Res. Commun. 2002. V. 291. P. 146-149.

- Kasche V., Ignatova Z., Markl H., et al. // Biotechnol. Prog. 2005. V. 21. P. 432-438.

- Chou C.P., Yu C.C., Tseng J.H., et al. // Biotechnol. Bioeng. 1999. V. 63. P. 263-272.

- Cai G., Zhu S., Yang S., et al. // Appl. Environ. Microbiol. 2004. V. 70. P. 2764-2770.

- Zhang L.F., Li Z.W., Zhang Q.J. // Chin. J. Biotechnol. 1991. V. 7. P. 63-72.

- Martin L., Prieto M.A., Cortes E., et al. // FEMS Microbiol. Lett. 1995. V. 125. P. 287-292.

- Polderman-Tijmes J. J., Jekel P.A., de Vries E.J., et al. // Appl. Environ. Microbiol. 2002. V. 68. P. 211-218.

- Kang H.K., Park J.Y., Ahn J.S., et al. // J. Microbiol. Biotechnol. 2009. V. 19. P. 172-177.

- Lu Y., Chi X., Yang Q., et al. // Extremophiles. 2009. V. 13. P. 875-884.

- Lu Y., Zhao H., Zhang C., et. al. // Biotechnol. Lett. 2009. V. 31. P. 1525-1530.

- Madhavan A., Tamalampudi S., Ushida K., et al. // Appl. Microbiol. Biotechnol. 2009. V. 82. P 1067-1078.

- Karimi M., De Meyer B., Hilson P // Trends. Plant. Sci. 2005. V. 10. P 103-105.

- Karimi M., Depicker A., Hilson P // Plant. Physiol. 2007. V. 145. P 1144-1154.

- Sando T., Takeno S., Watanabe N. // Biosci. Biotechnol. Biochem. 2008. V. 72. P. 2903-2917.

- Cao Y., Lu Z., Sun P., et al. // Wei Sheng Wu Xue Bao. 2008. V. 48. P. 312-316.

- Khodabandehloo M., Shamsi Shahrabadi M., Keyvani H. // Iran Biomed. J. 2009. V. 13. P 9-18.

- Liu Z., Yang G., Li B. // Mol. Biotechnol. 2003. V. 24. P. 21-26.

- Liu Z., Yang G.Z., Chi C.W., et al. // Protein. Pept. Lett. 2002. V. 9. P. 419-426.

- Farrokhi N., Hrmova M., Burton R.A., et al. // Methods Mol. Biol. 2009. V. 513. P 175-198.

- Schwarz D., Dotsch V., Bernhard F. // Proteomics. 2008. V. 8. P. 3933-3946.

- Schwarz D., Junge F., Durst F., et al. // Nat. Protoc. 2007. V. 2. P 2945-2957.

- Spirin A.S. // Bioorgan. khimia (Bioorganic Chemistry).1992. V. 18. P 1394-1402.

- Oh S.J., Kim Y.C., Park Y.W., et al. // Gene. 1987. V. 56. P. 87-97.

- Chou C.P., Kuo B.Y., Lin W.J. // J. Biosci. Bioeng. 1999. V. 88. P 160-167.

- Ohashi H., Katsuta Y., Nagashima M., et al. // Appl. Environ. Microbiol. 1989. V. 55. P. 1351-1356.

- Daumy G.O., Williams J.A., McColl A.S., et al. // J. Bacteriol. 1986. V. 168. P. 431-433.

- Barbero J.L., Buesa J.M., Gonzalez de Buitrago G., et al. // Gene. 1986. V. 49. P. 69-80.

- Meevootisom V., Somsuk P., Prachaktam R., et al. // Appl. Environ. Microbiol. 1983. V. 46. P 1227-1229.

- Dai M., Zhu Y., Yang Y., et al. // Eur. J. Biochem. 2001. V. 268. P. 1298-1303

- Ignatova Z., Mahsunah A., Georgieva M., et al. // Appl. Environ. Microbiol. 2003. V. 69. P 1237-1245.

- Jiang Y.M., Tong W.Y., Wei D.Z. // Biotechnol. Prog. 2007. V. 23. P. 1031-1037.

- Norris V., Grant S., Freestone P., et al. // J. Bacteriol. 1996. V. 178. P 3677-3682.

- Scherrer S., Robas N., Zouheiry H., et al. // Appl. Microbiol. Biotechnol. 1994. V. 42. P 85-91.

- Xu Y., Rosenkranz S., Weng C.L., et al. // Appl. Microbiol. Biotechnol. 2006. V. 72. P 529-536.

- Berks B.C., Sargent F., Palmer T. // Mol. Microbiol. 2000. V. 35. P 260-274.

- Narayanan N., Xu Y., Chou C.P // Biotechnol. Prog. 2006. V. 22. P. 1518-1523.

- Xu Y., Weng C.L., Narayanan N., et al. // Appl. Environ. Microbiol. 2005. V. 71. P. 6247-6253.

- Maresova H., Stepanek V., Kyslik P // Biotechnol. Bioeng. 2001. V. 75. P 46-52.

- Sriubolmas N., Panbangred W., Sriurairatana S., et al. // Appl. Microbiol. Biotechnol. 1997. V. 47. P. 373-378.

- Vohra P.K., Sharma R., Kashyap D.R., et al. // Biotechnol. Lett. 2001. V. 23. P. 531-535.

- De Leon A., Breceda G.B., Barba de la Rosa A.P., et al. // Biotechnol. Lett. 2003. V. 25. P 1397-1402.

- Huang S.W., Lin Y.H., Chin H.L., et al. // Biotechnol. Prog. 2002. V. 18. P 668-671.

- Deak P.M., Lutz-Wahl S., Bothe H., et al. // Biotechnol. Lett. 2003. V. 25. P 397-400.

- Oinonen C., Rouvinen J. // Protein. Sci. 2000. V. 9. P. 2329-2337.

- Svyadas V.K., Margolin A.L., Sherstuk S.F., et al. // Bioorgan. khimia (Bioorgan. Chemistry). 1977. V. 3. P. 546-554.

- Brannigan J.A., Dodson G., Duggleby H.J. // Nature. 1995. V. 378. P 416-419.

- Alkema W.B., Hensgens C.M., Snijder H.J., et al. // Protein. Eng. Des. Sel. 2004. V. 17. P. 473-480.

- Alkema W.B., Prins A.K., de Vries E., et al. // Biochem. J. 2002. V. 365. P. 303-309.

- McVey C.E., Walsh M.A., Dodson G.G., et al. // J. Mol. Biol. 2001. V. 313. P. 139-150.

- Alkema W.B., Hensgens C.M., Kroezinga E.H., et al. // Protein. Eng. 2000. V. 13. P 857-863.

- Done S.H., Brannigan J.A., Moody P.C., et al. // J. Mol. Biol. 1998. V. 284. P 463-475.

- Gololobov M.Yu., Borisov I.L., Svedas V.K. // J. Theor. Biol. 1989. V. 140. P. 193-204.

- Youshko M.I., Bukhanov A.L., Svedas V.K. // Biochemistry (Moscow). 2003. V. 68. N 3. P 334-338.

- Jager S.A.W., Jekel P.A., Janssen D.B. // Enzyme Microb. Technol. 2007. V. 40. P. 1335-1344.

- Gabor E.M., Janssen D.B. // Protein Eng. Des. Sel. 2004. V. 17. P. 571-579.

- Margolin A.L., Svedas V.K., Berezin I.V., et al. // Biochim. Biophys. Acta. 1980. V. 616. P 283-289.

- Guranda D.T., van Langen L.M., van Rantwijk F., et al. // Tetrahedron. Asym. 2001. V. 12. P 1645-1650.

- Oh B., Kim K., Park J., et al. // Biochem. Biophys. Res. Commun. 2004. V. 319. P 486-492.

- Alkema W.B., Dijkhuis A.J., De Vries E., et al. // Eur. J. Biochem. 2002. V. 269. P. 2093-2100.

- Jager S.A., Shapovalova I.V., Jekel P.A., et al. // J. Biotechnol. 2008. V. 133. P 18-26.

- Shapovalova I.V., Alkema W.B.L., Jamskova O.V., et al. // Acta Naturae. 2009. V. 1. N 3. P. 94-98.

- Flores G., Soberon X., Osuna J. // Protein Sci. 2004. V. 13. P. 1677-1683.

- Wang T., Zhu H., Ma X., et al. // Protein. Pept. Lett. 2006. V. 13. P. 177-183.

Supplementary files